China OEM desturi alloy chuma castings namchakato wa kutupa uwekezaji wa wax uliopotea. Chuma cha kaboni, chuma cha aloi ya chini, na utengenezaji wa chuma cha zana hutumiwa katika kadhaamaombi ya viwandanagia zilizobinafsishwa. Kwa viwango vyao vingi, chuma na aloi zao zinaweza kutibiwa kwa joto ili kuboresha mavuno yake na nguvu za mkazo; na, kurekebisha ugumu au ductility kwa mahitaji ya maombi ya mhandisi au sifa taka mitambo.

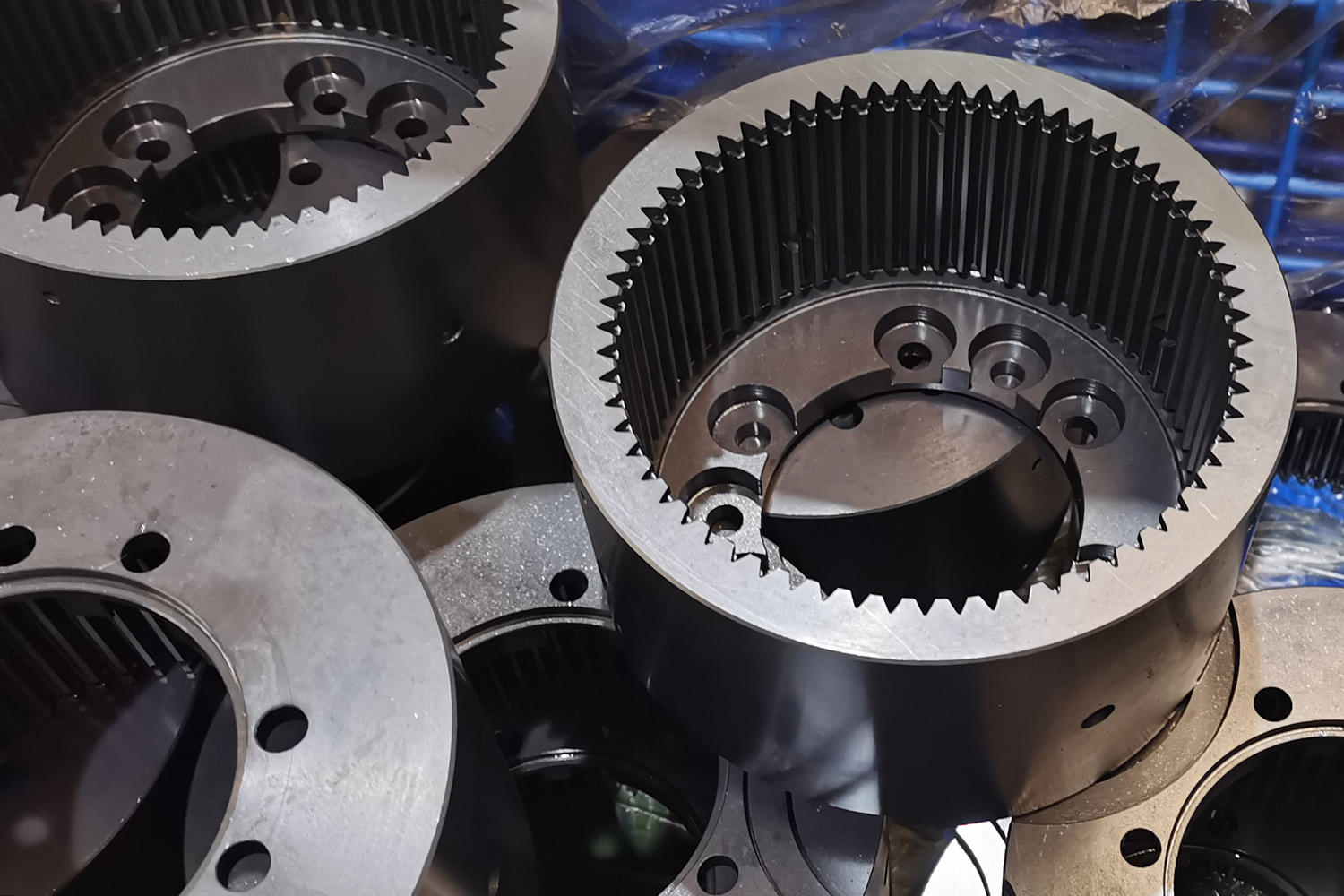

Vitega uchumi vya aloi vinavyostahimili uvaaji ni sehemu za utupaji zinazozalishwa na mchakato wa utupaji wa uwekezaji wa nta uliopotea uliotengenezwa kwa chuma cha aloi kinachostahimili kuvaa. Katika RMC Foundry, michakato kuu ya utupaji mchanga tunayoweza kutumia kwa chuma cha aloi sugu ni utupaji wa mchanga wa kijani kibichi, utupaji wa mchanga uliofunikwa na resini, utupaji wa ukungu wa mchanga usiooka, utupaji wa povu uliopotea, utupaji wa utupu na uwekaji uwekezaji. Matibabu ya joto, matibabu ya uso na usindikaji wa CNC pia zinapatikana katika kiwanda chetu kulingana na michoro na mahitaji yako.

Miongoni mwa aina mbalimbali za aloi za kutupwa, chuma cha kutupwa kinachostahimili kuvaa ni chuma cha aloi kinachotumiwa sana. Chuma cha kutupwa kinachostahimili uvaaji huboresha hali ya ustahimilivu wa uvaaji wa uwekaji chuma kwa kuongeza maudhui tofauti ya vipengele vya aloi, kama vile manganese, chromium, kaboni, n.k., kwenye aloi. Wakati huo huo, upinzani wa kuvaa kwa castings za chuma zisizovaa pia hutegemea njia ya matibabu ya joto inayotumiwa na msingi na muundo wa kutupwa.

Kulingana na sifa tofauti za uvaaji, uvaaji wa castings wa chuma unaweza kugawanywa katika kuvaa kwa abrasive, kuvaa wambiso, kuvaa kwa uchovu, kuvaa kutu na kuvaa kwa fretting. Majumba ya chuma yanayostahimili uvaaji hutumika zaidi katika nyanja za viwanda zilizo na hali ngumu ya kufanya kazi na mahitaji ya juu ya utendakazi wa kiufundi, kama vile uchimbaji madini, madini, ujenzi, nishati, petrokemikali, uhifadhi wa maji, kilimo na tasnia ya usafirishaji. Matunzio ya chuma yanayostahimili uvaaji hutumiwa zaidi katika hali ya mikwaruzo na mzigo fulani wa athari, kama vile vifaa vya kusaga, vichimbaji, viponda, trekta, n.k.

| Kiwango Sawa cha Chuma cha Aloi ya Cast kutoka Masoko Tofauti | |||||||||

| VIKUNDI | AISI | W-stoff | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| Chuma cha Aloi ya Chini | 9255 | 1.0904 | 55 hadi 7 | 250 A 53 | 2090 | 55 S 7 | 56Si7 | - | 5SSi8 |

| 1335 | 1.1167 | 36 Mb 5 | 150 M 36 | 2120 | 40 m 5 | 36Mn5 | SMn 438(H) | - | |

| 1330 | 1.1170 | 28 Mb 6 | 150 M 28 | - | 20 m 5 | - | SCMn1 | C28MN | |

| P4 | 1.2341 | X6 CrMo 4 | - | - | - | - | - | - | |

| 52100 | 1.3505 | 100 Kr 6 | 534 A99 | 2258 | 100 C 6 | F.131 | SUJ 2 | 100Cr6 | |

| A204A | 1.5415 | 15 Mo 3 | 1501 240 | 2912 | 15 D 3 | 16 Mo3 | STBA 12 | 16Mo3 KW | |

| 8620 | 1.6523 | 21 NiCrMo 2 | 805 M 20 | 2506 | 20 NCD 2 | F.1522 | SNCM 220(H) | 20NiCrMo2 | |

| 8740 | 1.6546 | 40NiCrMo22 | 311-Aina ya 7 | - | 40 NCD 2 | F.129 | SNCM 240 | 40NiCrMo2(KB) | |

| - | 1.6587 | 17CrNiMo6 | 820 A16 | - | 18 NCD 6 | 14NiCrMo13 | - | - | |

| 5132 | 1.7033 | 34 Kr 4 | 530 A 32 | - | 32 C 4 | 35Kr4 | SCr430(H) | 34Cr4(KB) | |

| 5140 | 1.7035 | 41 Kr 4 | 530 A 40 | - | 42 C 2 | 42 Kr 4 | SCr 440 (H) | 40Kr4 | |

| 5140 | 1.7035 | 41 Kr 4 | 530 A 40 | - | 42 C 2 | 42 Kr 4 | SCr 440 (H) | 41Cr4 KB | |

| 5140 | 1.7045 | 42 Kr 4 | 530 A 40 | 2245 | 42 C 4 TS | F.1207 | Sehemu ya 440 | - | |

| 5115 | 1.7131 | 16 MnCr 5 | (527 M 20) | 2511 | 16 MC 5 | F.1516 | - | 16MnCr5 | |

| 5155 | 1.7176 | 55 Kr 3 | 527 A 60 | 2253 | 55 C 3 | - | SUP 9(A) | 55Kr3 | |

| 4130 | 1.7218 | 25 CrMo 4 | 1717CDS 110 | 2225 | 25 CD4 | F.1251/55Cr3 | SCM 420 / SCM430 | 25CrMo4(KB) | |

| 4135 (4137) | 1.7220 | 35 CrMo 4 | 708 A 37 | 2234 | 35 CD 4 | 34 CrMo 4 | SCM 432 | 34CrMo4KB | |

| 4142 | 1.7223 | 41 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 TS | 42 CrMo 4 | SCM 440 | 41 CrMo 4 | |

| 4140 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 40 CD4 | F.1252 | SCM 440 | 40CrMo4 | |

| 4137 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 42 CD4 | F.1252 | SCM 440 | 42CrMo4 | |

| A387 12-2 | 1.7337 | 16 CrMo 4 4 | 1501 620 | 2216 | 15 CD 4.5 | - | - | 12CrMo910 | |

| - | 1.7361 | 32CrMo12 | 722 M 24 | 2240 | 30 CD12 | F.124.A | - | 30CrMo12 | |

| A182 F-22 | 1.7380 | 10 CrMo9 10 | 1501 622 | 2218 | 12 CD 9, 10 | F.155 / TU.H | - | 12CrMo9 10 | |

| 6150 | 1.8159 | 50 CRV 4 | 735 A50 | 2230 | 50 CV 4 | F.143 | SUP 10 | 50CrV4 | |

| - | 1.8515 | 31 CrMo 12 | 722 M 24 | 2240 | 30 CD12 | F.1712 | - | 30CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Chuma cha Aloi ya Kati | W1 | 1.1545 | C105W1 | BW1A | 1880 | Y 105 | F.5118 | SK 3 | C100 KU |

| L3 | 1.2067 | 100Cr6 | BL 3 | (2140) | Y 100 C 6 | F.520 L | - | - | |

| L2 | 1.2210 | 115 CrV 3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 | 40 CrMnMoS 8 6 | - | - | 40 CMD 8 +S | X210CrW12 | - | - | |

| - | 1.2419 | 105WCr6 | - | 2140 | 105W C 13 | F.5233 | SKS 31 | 107WCr5KU | |

| O1 | 1.2510 | 100 MnCrW 4 | BO1 | - | 90MnWCRV5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 | 45 WCRV 7 | BS1 | 2710 | 55W20 | F.5241 | - | 45WCrV8KU | |

| 4340 | 1.6582 | 34 CrNiMo 6 | 817 M 40 | 2541 | 35 NCD 6 | F.1280 | SNCM 447 | 35NiCrMo6KB | |

| 5120 | 1.7147 | 20 MnCr 5 | - | - | 20 MC 5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Chombo na chuma cha Aloi ya Juu | D3 | 1.2080 | X210 Cr 12 | BD3 | 2710 | Z200 C 12 | F.5212 | SKD 1 | X210Cr13KU |

| P20 | 1.2311 | 40 CrMnMo 7 | - | - | 40 CMD 8 | F.5263 | - | - | |

| H13 | 1.2344 | X40CrMoV 5 1 | BH13 | 2242 | Z 40 CDV 5 | F.5318 | SKD 61 | X40CrMoV511KU | |

| A2 | 1.2363 | X100 CrMoV 5 1 | BA2 | 2260 | Z 100 CDV 5 | F.5227 | SKD 12 | X100CrMoV51KU | |

| D2 | 1.2379 | X155 CrMoV 12 1 | BD2 | 2310 | Z 160 CDV 12 | F.520.A | SKD11 | X155CrVMo121KU | |

| D4 (D6) | 1.2436 | X210 CrW 12 | BD6 | 2312 | Z 200 CD 12 | F.5213 | SKD 2 | X215CrW121KU | |

| H21 | 1.2581 | X30WCRV9 3 | BH21 | - | Z 30 WCV 9 | F.526 | SKD5 | X30WCrV 9 3 KU | |

| L6 | 1.2713 | 55NiCrMoV 6 | - | - | 55 NCDV 7 | F.520.S | SKT4 | - | |

| M 35 | 1.3243 | S6/5/2/5 | BM 35 | 2723 | 6-5-2-5 | F.5613 | SKH 55 | HS6-5-5 | |

| M 2 | 1.3343 | S6/5/2 | BM2 | 2722 | Z 85 WDCV | F.5603 | SKH 51 | HS6-5-2-2 | |

| M 7 | 1.3348 | S2/9/2 | - | 2782 | 2 92 | - | - | HS2-9-2 | |

| HW 3 | 1.4718 | X45CrSi 9 3 | 401 S 45 | - | Z 45 CS 9 | F.3220 | SUH1 | X45CrSi8 | |

| - | 1.7321 | 20 MoCr 4 | - | 2625 | - | F.1523 | - | 30CrMo4 | |

| Chuma chenye Nguvu ya Juu | A128 (A) | 1.3401 | G-X120 Mn 12 | BW10 | 2183 | Z 120 M 12 | F.8251 | SCMnH 1 | GX120Mn12 |

Uwezo waUwekezaji Casting Foundry:

• Ukubwa wa Juu: 1,000 mm × 800 mm × 500 mm

• Uzito mbalimbali: 0.5 kg - 100 kg

• Uwezo wa Mwaka: tani 2,000

• Nyenzo za Bondi za Ujenzi wa Shell: Silika Sol, Glasi ya Maji na michanganyiko yake.

• Uvumilivu: Kwa Ombi.

Faida zaVipengele vya Uwekezaji wa Uwekezaji:

- Kumaliza bora na laini ya uso

- Uvumilivu mkali wa dimensional.

- Maumbo changamano na changamano na unyumbufu wa muundo

- Uwezo wa kutupa kuta nyembamba kwa hiyo ni sehemu nyepesi ya kutupa

- Uchaguzi mpana wa metali za kutupwa na aloi (feri na zisizo na feri)

- Rasimu haihitajiki katika muundo wa molds.

- Kupunguza haja ya machining sekondari.

- Upotevu wa chini wa nyenzo.

| Nyenzo zaUwekezaji AkitoaMchakato katika RMC Foundry | |||

| Kategoria | Daraja la China | Daraja la Marekani | Daraja la Ujerumani |

| Chuma cha pua cha Ferritic | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Chuma cha pua cha Martensitic | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic chuma cha pua | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.44404, 1.4404, 9 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Mvua Inaimarisha Chuma cha pua | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Chuma cha pua cha Duplex | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Chombo cha Chuma | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Chuma Kinachostahimili Joto | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Aloi ya msingi wa Nickle | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Alumini Aloi | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Aloi ya Shaba | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Aloi ya msingi ya Cobalt | UMC50, 670, Daraja la 31 | 2.4778 | |

| UVUMILIVU WA KUTUPIA UWEKEZAJI | |||

| Inchi | Milimita | ||

| Dimension | Uvumilivu | Dimension | Uvumilivu |

| Hadi 0.500 | ±.004" | Hadi 12.0 | ± 0.10mm |

| 0.500 hadi 1,000" | ±.006" | 12.0 hadi 25.0 | ± 0.15mm |

| 1,000 hadi 1.500" | ±.008" | 25.0 hadi 37.0 | ± 0.20mm |

| 1.500 hadi 2,000" | ±.010" | 37.0 hadi 50.0 | ± 0.25mm |

| 2,000 hadi 2.500" | ±.012" | 50.0 hadi 62.0 | ± 0.30mm |

| 2.500 hadi 3.500" | ±.014" | 62.0 hadi 87.0 | ± 0.35mm |

| 3.500 hadi 5,000" | ±.017" | 87.0 hadi 125.0 | ± 0.40mm |

| 5,000 hadi 7.500" | ±.020" | 125.0 hadi190.0 | ± 0.50mm |

| 7.500 hadi 10,000" | ±.022" | 190.0 hadi 250.0 | ± 0.57mm |

| 10,000 hadi 12.500" | ±.025" | 250.0 hadi 312.0 | ± 0.60mm |

| 12.500 hadi 15,000 | ±.028" | 312.0 hadi 375.0 | ± 0.70mm |