Chuma cha pua kina kiwango cha chini cha chromium cha 10.5%, na kuifanya kustahimili mazingira ya kioevu babuzi na uoksidishaji. Inastahimili kutu kwa kiwango cha juu na hustahimili uvaaji, hutoa uwezo bora wa kufanya kazi, na inajulikana sana kwa mwonekano wake wa urembo. Uwekezaji wa chuma cha pua "hustahimili kutu" unapotumiwa katika mazingira ya kioevu na mivuke iliyo chini ya 1200°F (650°C) na "kinga joto" inapotumiwa juu ya halijoto hii.

Daraja Sawa la Chuma cha pua | |||||||

| Kategoria | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Chuma cha pua cha Martensitic na Ferritic | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Kr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (S410) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 ClAl 13 | 405 S 17 | - | F.3111 | X6 ClAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Kr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Kr 13 | 420 S45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S17 | - | - | X6CrTi12 | |

| Chuma cha pua cha Austenitic | 304 | 1.4301 | X5 CrNi 18 9 | 304 S15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Chuma cha pua cha Duplex | S32750 | 1.4410 | X 2 CrNiMon 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMon 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Nyenzo za Feri na Zisizo na Feri za Uwekezaji, Mchakato wa Utupaji wa Nta Uliopotea:

- • Chuma cha Kijivu: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

- • Ductile Iron au Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Chuma cha Carbon: AISI 1020 - AISI 1060, C30, C40, C45.

- • Aloi za Chuma: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...nk kwa ombi.

- • Chuma cha pua: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 na daraja nyingine za chuma cha pua.

- • Shaba, Shaba Nyekundu, Shaba au aloi nyinginezo zenye msingi wa Shaba: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Nyenzo Nyingine kulingana na mahitaji yako ya kipekee au kulingana na ASTM, SAE, AISI, ACI, DIN, EN, ISO, na viwango vya GB

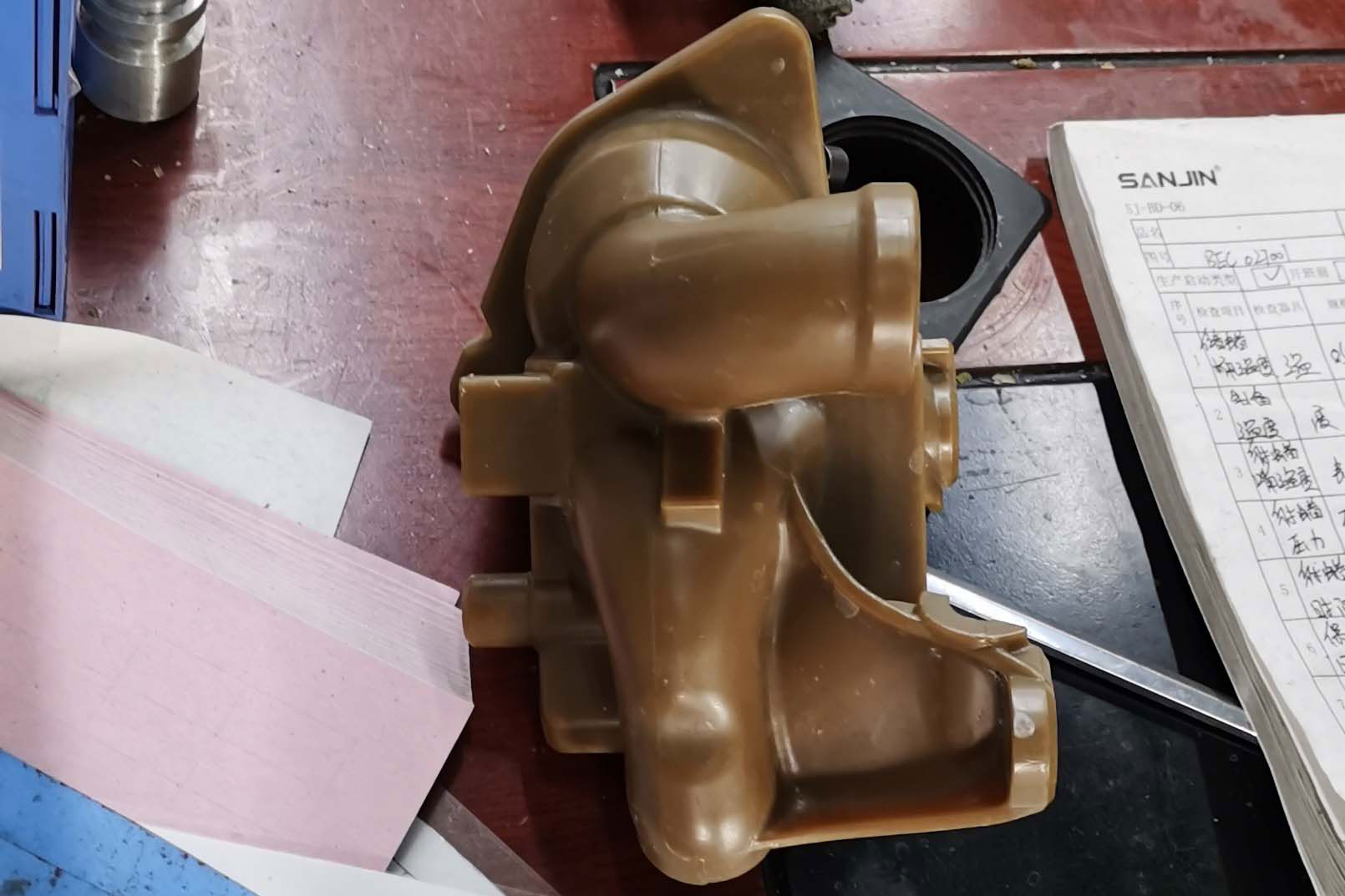

Utumiaji wa Sehemu Zetu Maalum za Utumaji na Uchimbaji:

- 1. Sehemu za Gari: Diski ya Brake, Fimbo ya Kuunganisha, Axle ya Kuendesha, Shaft ya Kuendesha, Udhibiti wa Arm, Gearbox Housing, Jalada la Gearbox, Clutch Cover, Clutch Housing, Magurudumu, Nyumba ya Kichujio, Nyumba ya Pamoja ya CV, Hook ya Kufungia.

- 2. Sehemu za Lori: Mikono ya Rocker, Gearbox ya Usambazaji, Axles za Kuendesha, Gear Housing, Gear Cover, Towing Eye, Connect Rod, Engine Block, Engine Cover, Joint Bolt, Power Takeoff, Crankshaft, Camshaft, Pan ya Mafuta.

- 3. Sehemu za Hydraulic: Hydraulic Cylinder, Hydraulic Pump, Gerotor Housing, Vane, Bushing, Hydraulic Tank, Hydraulic Cylinder Head, Hydraulic Cylinder Triangle Bracket.

- 4. Mitambo ya Kilimo na Sehemu za Trekta: Nyumba ya Gia, Jalada la Gia, Fimbo ya Kuunganisha, Fimbo ya Torque, Kizuizi cha Injini, Kifuniko cha Injini, Nyumba ya Pampu ya Mafuta, Mabano, Hanger, Hook, Bracket.

- 5. Treni za Reli na Magari ya Mizigo: Makazi ya Mshtuko wa Mshtuko, Jalada la Kufyonza Mshtuko, Makazi ya Rasimu ya Gia, Jalada la Gia, Kabari na Koni, Magurudumu, Mifumo ya Breki, Mipini, Miongozo.

- 6. Sehemu za Mitambo ya Ujenzi: Gear, Kiti cha Kubeba, Pampu ya Gear, Nyumba ya Gearbox, Jalada la Gearbox, Flange, Bushing, Silinda ya Boom, Bracket ya Msaada, Tangi ya Hydraulic, Meno ya Ndoo, Ndoo.

- 7. Sehemu za Vifaa vya Vifaa: Magurudumu, Caster, Bracket, Hydraulic Cylinder, Forklift Spare Parts, Lock Case.

- 8. Sehemu za Valve na Pampu: Mwili wa Valve (Nyumba), Diski ya Valve ya Butterfly, Nyumba ya Valve ya Mpira, Flange, Kiunganishi, Camlock, Impeller ya Fungua, Impeller ya Funga, Nyumba ya Pampu (Mwili), Kifuniko cha Pampu.

Matibabu ya joto ya AISI 316 ya Utumaji wa Chuma cha pua:

Joto hadi 1900°F (1040°C) kima cha chini kabisa, ukishikilia kwa muda wa kutosha, zima katika maji au upoe kwa haraka kwa njia nyinginezo. AISI 316 sawa na CF8M/F316 na Kiwango cha Kichina 0Cr17Ni12Mo2. AISI 314 ni muundo wa molybdenum yenye aloi ya AISI 304 na ni aloi ya kutupwa sawa na chuma cha pua cha CF8M. Uwepo wa molybdenum huongeza upinzani wa kutu kwa ujumla na upinzani wa kupenya kwa kloridi. Aloi hutumiwa katika hali ya asidi kidogo na ya alkali na kwa kushughulikia asidi ya citric, oxalic na fosforasi.