Nyumba maalum za vali za chuma cha pua duplex zinazozalishwa kwa uchezaji wa uwekezaji kutoka Chinamashine, matibabu ya joto, na huduma za matibabu ya uso.

Waigizaji wa RMCsehemu za chuma zilizopigwa kwa usahihiambayo mara kwa mara inakidhi au kuzidi matarajio ya wateja. Uwekezaji wa nta uliopotea huturuhusu kuzalishabidhaa za kutupwa chuma cha puandogo kama makumi ya gramu na kubwa kama makumi ya kilo, katika anuwai ya aloi za feri na zisizo na feri na kwa usahihi wa kipekee wa dimensional.

Mchakato wa utupaji wa uwekezaji wa nta uliopotea hutokeza uigizaji wa usahihi wa umbo la karibu ambao mara nyingi huhitaji uchakataji mdogo au kutohitaji kabisa. Kumaliza matokeo pia ni bora zaidi kuliko kile kinachoweza kupatikana kupitia michakato mingine ya utupaji au utengenezaji. Uimara na uimara wa visehemu vya kutupwa hujifanya kuwa bora kwa programu zinazostahimili uvaaji zinazohitaji mamilioni ya mizunguko.

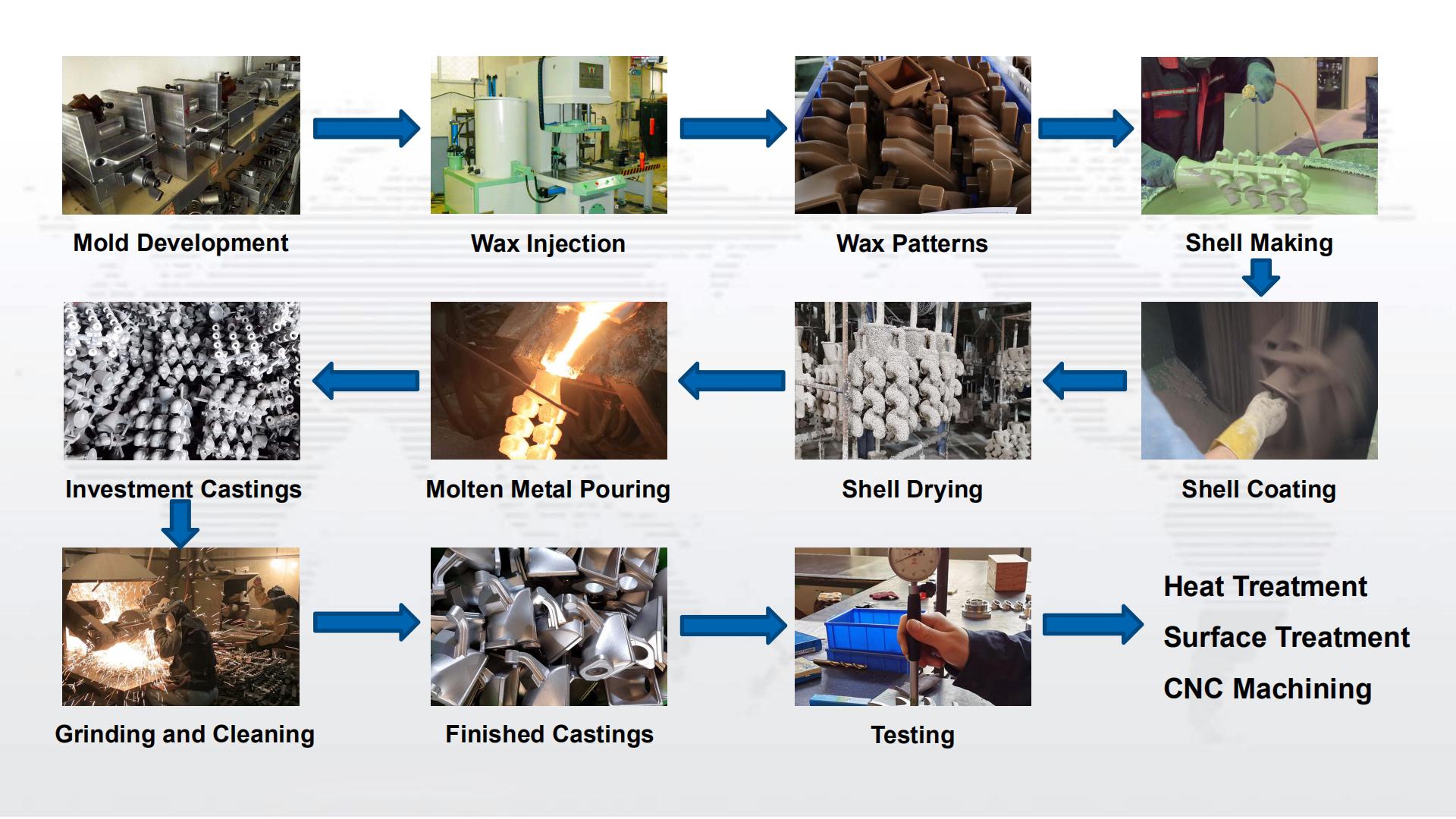

Hatua za Mchakato wa Uwekezaji wa Uwekezaji:

Wakati wa mchakato wa kutupa uwekezaji, muundo wa wax huwekwa na nyenzo za kauri, ambazo, wakati ugumu, hupitisha jiometri ya ndani ya kutupa taka. Mara nyingi, sehemu nyingi hutupwa pamoja kwa ufanisi wa hali ya juu kwa kuambatanisha ruwaza za nta kwenye kijiti cha kati cha nta kiitwacho sprue. Nta inayeyushwa kutoka kwa muundo - ndiyo sababu inajulikana pia kama mchakato wa nta uliopotea - na chuma kilichoyeyuka hutiwa ndani ya shimo. Wakati chuma kikiimarisha, mold ya kauri inatikiswa, na kuacha sura ya karibu ya wavu wa kutupa taka, ikifuatiwa na kumaliza, kupima na ufungaji.

Chuma cha pua cha Duplex (DSS) kinarejelea chuma cha pua chenye feri na austenite kila moja ikichukua takriban 50%. Kwa ujumla, maudhui ya awamu ndogo yanahitaji kuwa angalau 30%. Katika hali ya maudhui ya chini ya C, maudhui ya Cr ni 18% hadi 28%, na maudhui ya Ni ni 3% hadi 10%. Baadhi ya vyuma viwili vya pua pia vina vipengele vya aloi kama vile Mo, Cu, Nb, Ti, na N.

Daraja linalopatikana la chuma cha pua cha duplex katika RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890, 5 A9 A8 A9A 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS ina sifa za chuma cha pua cha austenitic na ferritic. Ikilinganishwa na feri, ina kinamu na unyumbufu wa juu zaidi, haina brittleness ya joto la kawaida, na imeboresha kwa kiasi kikubwa upinzani wa kutu kati ya punjepunje na utendakazi wa kulehemu, huku ingali ikidumisha upesi, upitishaji joto wa juu, na uthabiti wa hali ya juu kama ferrite chuma cha pua. Ikilinganishwa na chuma cha pua cha austenitic, DSS ina nguvu ya juu na imeboresha kwa kiasi kikubwa upinzani dhidi ya kutu kati ya punjepunje na kutu ya mkazo wa kloridi. Duplex chuma cha pua kina upinzani bora wa kutu wa shimo na pia ni chuma cha pua kinachookoa nikeli.

| Daraja Sawa la Chuma cha pua | |||||||

| VIKUNDI | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Chuma cha pua cha Martensitic na Ferritic | 420 C | 1,4034 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Kr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (S410) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 ClAl 13 | 405 S 17 | - | F.3111 | X6 ClAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Kr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Kr 13 | 420 S45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S17 | - | - | X6CrTi12 | |

| Chuma cha pua cha Austenitic | 304 | 1.4301 | X5 CrNi 18 9 | 304 S15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Chuma cha pua cha Duplex | S32750 | 1.4410 | X 2 CrNiMon 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMon 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Vyuma vya Feri na Vyuma visivyo na feri kwaUwekezaji Akitoa, Mchakato wa Kutupa Nta Uliopotea:

• Chuma cha Kijivu: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Ductile Iron au Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Chuma cha Carbon: AISI 1020 - AISI 1060, C30, C40, C45.

• Aloi za Chuma: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...nk kwa ombi.

• Chuma cha pua: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 na daraja nyingine za chuma cha pua.

• Shaba, Shaba Nyekundu, Shaba au aloi nyinginezo zenye msingi wa Shaba: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Nyenzo Nyingine kulingana na mahitaji yako ya kipekee au kulingana na ASTM, SAE, AISI, ACI, DIN, EN, ISO, na viwango vya GB

▶ Uwezo waUwekezaji Casting Foundry

• Ukubwa wa Juu: 1,000 mm × 800 mm × 500 mm

• Uzito mbalimbali: 0.5 kg - 100 kg

• Uwezo wa Mwaka: tani 2,000

• Nyenzo za Bondi za Ujenzi wa Shell: Silika Sol, Glasi ya Maji na michanganyiko yake.

| Huduma | Maelezo |

| Huduma za Matibabu ya uso | Upakaji wa Poda, Uwekaji Anodization, Electrophotesis, Uwekaji wa Chrome, Uchoraji, Ulipuaji wa Mchanga, Uwekaji wa Nickel, Uwekaji wa Zinki, Uwekaji Nyeusi, Ung'arisha, Bluing, Geormet, Zintek, n.k. |

| Huduma za Uchimbaji wa Usahihi wa CNC | Lathing, Milling, Turning, Honing, Drilling, Boring, Tapping, Waya Electrode Cutting, Kusaga...nk. |

| Ukaguzi na Udhibiti wa Ubora | Spectrum Analyzer, CMM, Hardness Tester, Tensile Strength Tester, Yild Strentgh Testor, Sealing Pressure Tester, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester...n.k. |